Machine technology 4.0

With the step towards Industry 4.0, we are already moving into the future today. We are digitising and automating our workflows and processes with the introduction of state-of-the-art technology. An important foundation stone for the "smart ironworks".

The aim of continuous further development is to maintain our high quality standards and renowned reliability, even with faster and more efficient production. The further expansion of comprehensive product lines with the integration of combination devices such as the versatile "Combi Genius" punch laser enables the production of complex parts at high speed. Among other things, we are currently working with a punched part tool turret with 16 stations. This holds up to 384 simple or 128 rotating tools in the turret and therefore allows tools to be changed quickly and effectively. 300kN are available for punching. Formings such as roll beads, gills and the like can be moulded up to a height of 15 mm.

The average age of our machinery is currently around 5 years and we are constantly investing in its expansion. in 2023, we will install a new powder coating system. An automatic bending centre and a 6kW fibre laser cutting system are currently being planned.

For the production of our UP-fix® and the Allmess flush-mounted water meter line, we have specially manufactured, highly economical special tools, e.g. an induction soldering machine from steremat, assembly and testing machine from techVision and others at our disposal

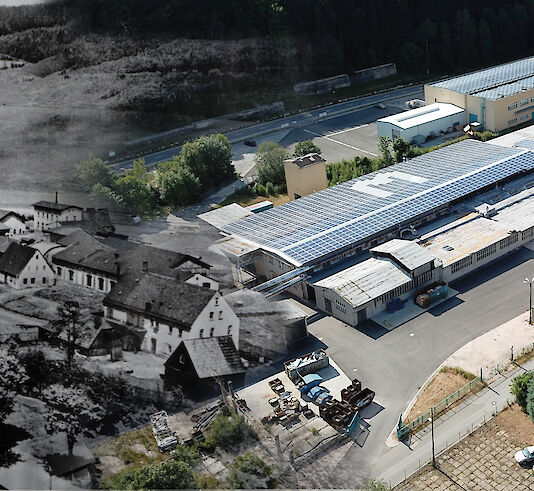

In this way, our lines guarantee the highest processing quality with high efficiency. Thanks to Industry 4.0, we can also place a strong focus on sustainability, economy and resource conservation. The smart integration of our extensive photovoltaic systems into production is a matter of course. The main focus here is on reducing fossil fuels. We are also constantly working on reducing the use of hydraulic oil, minimising heat and noise emissions and lowering CO2 consumption.